Offshore & Domestic Machined Components

Single Source Responsibility - We Eliminate Your Risk!

Supply Chain Experts

Take Advantage of Our 15 Plus Years of Experience

Quality Assurance

Every part we source or manufacture is ISO 9001 compliant

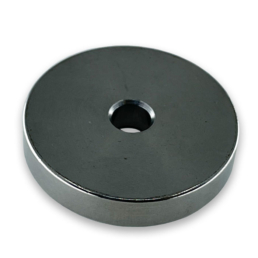

Single-source domestic and offshore manufacturing of top-quality precision machined components.

Our proprietary process enables us to achieve 97% on-time deliveries and near zero customer returns.

We offer a wide variety of manufacturing methods, including CNC machining, stamping, casting, forging, cold forming, extrusion, injection molding, powdered metal, and more. Global Sourcing Services will match your needed volume with the best price and the best quality and deliver it to you at the best lead-time possible.

Our Mission

We work with our global network of vetted suppliers to find the right manufacturing partner for your product at the best price, quality, and lead-time.

We assume project responsibility by handling every step, from pre-production to shipping to inventory management which allows us to deliver your parts on time with near-zero defects.

We are not brokers!

We are seasoned manufacturing experts with a vast understanding of different manufacturing processes that allows our customer base the confidence to depend on GSS as their one-stop shop organization.

Global Sourcing Services is a single-source supplier of high-quality CNC machined components and parts. We’ll handle manufacturing, shipping, quality assurance, and inventory management for you, so you don’t have to manage half a dozen vendors for every project. GSS can be your answer to supplier consolidation. We also rescue troubled projects. No matter the stage of production, we can take over project management and assume responsibility, so you can stay on track.

Global Sourcing Services is not a broker service. We don’t just send your drawing to a supplier and hope for the best. We are highly experienced manufacturing professionals who understand how things are made. We can provide in-house prototyping with our FasTrak™ Department and we strive to deliver quality quotes —with the best price — as quickly as possible. . We understand the technical details of CNC manufacturing and are well versed in CNC machining best practices. Our logistics department has over 15 years of offshore shipping experience.

Whether you’re looking to offshore your project or stay on American soil, we can save you the time and hassle of finding a credible manufacturer yourself. We have long standing relationships with reliable CNC machining companies around the world and we work exclusively in non-tariff countries, so we can get you the best price for your project.

In addition to our certified offshore and domestic network of suppliers, Global Sourcing Services offers in-house CNC machining services at our facilities in Mansfield and Lancaster, Ohio. We have decades of experience creating custom machined parts. Our machine shops are equipped to handle various materials utilizing a wide range of CNC capabilities.

No-risk solutions, backed up by our quality assurance program and certified supplier network.

We’re constantly engaged in comprehensive due diligence practices to ensure exceptional production quality, so you don’t assume any risk in today’s quality driven environment.

We start by fully vetting each of our offshore and domestic suppliers. The process includes third-party quality audits and our own investigations. We only establish a relationship when they’ve met or exceeded all our expectations, and all our partners are subject to ongoing audits.

Once a project is underway, we’re in regular communication so we always know what’s happening with your parts. We stay on top of every step of the process so there are never any surprises, and we can react quickly if something changes throughout the process and promptly communicate any disruption to you, the customer.

Our partners conduct their own ISO 9001 inspections on every part. Once your parts are shipped to us, we do a second audit to verify that each unit meets ISO 9001 standards.

Proprietary Process

Global Sourcing Services operates based on a fine-tuned, multi-faceted system to ensure that you get exactly what you need. Every step of the process is protected by quality checks. This approach has produced 97% on-time deliveries over the past decade and a near zero customer return rate of 0.008%.

Logistics Expertise

We can get you offshore pricing without the hassle of monitoring global shipping by managing the logistics for you. Our team is highly resourceful, with deep knowledge of the global supply chain, so we can find the most efficient way to transport your parts. And with our commitment to excellent communication, you’ll remain updated every step of the way.

Inventory Options

GSS offers several innovative inventory management options to customers. These options include our 52-turn inventory program, scheduled release program, KanBan programs, and safety stock program. We can customize a solution that meets your exact needs and timetable, and we stay in regular contact to ensure ongoing efficiency.

Our Parent company

Manufacturing Experience and Company Overview

Global Sourcing Services is part of Rable Machine, Inc., an American precision machining company with 75 years of manufacturing experience. We are CNC precision machining experts with over 250 pieces of equipment onsite. Rable Machine is a 100% employee-owned company with two machine shops located in Mansfield and Lancaster OH. Rable has 150,000 square feet of production capacity.

Contact Us

Or fill out our Quick Contact Form

Send up to 5 drawings or your NDA form so we can get the process started!